Service to destroy magnetic data on hard disk permanently.

Dry Pipe Nitrogen Inerting (DPNI) technology was developed by Engineered Corrosion Solutions, LLC (ECS) and is used to control oxygen corrosion in dry pipe and/or preaction fire sprinkler systems. DPNI is executed by employing a “fill and purge” differential pressure cycle (breathing) within the sprinkler pipe network. With the level of oxygen corrosion reduced to near zero the effective life of the fire sprinkler system is greatly extended. Systems implement a DPNI corrosion control strategy should never develop leaks when maintained properly.

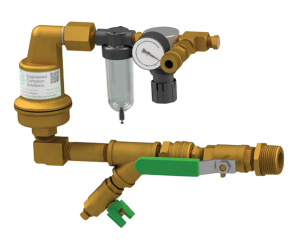

The AdvancedIQ Vent Controller (AVC) provides automatic oxygen venting, monitoring of nitrogen/oxygen concentration levels and monitoring of the sprinkler system pressure within each dry pipe/preaction fire sprinkler system. As a fire sprinkler system is filled with a continuous supply of nitrogen gas from the nitrogen generator system, the vent, installed on the sprinkler system riser, allows oxygen rich gas to be vented from the fire sprinkler system.

Dry Pipe Nitrogen Inerting (DPNI) technology was developed by Engineered Corrosion Solutions, LLC (ECS) and is used to control oxygen corrosion in dry pipe and/or preaction fire sprinkler systems. DPNI is executed by employing a “fill and purge” differential pressure cycle (breathing) within the sprinkler pipe network.